Have you ever experienced being unable to reach the planned distance in your fiber blowing jobs? In this article, we discuss five ways to maximize your fiber blowing distance.

Maximize your fiber blowing distance in five ways

1. Clean and lubricate the duct correctly

Sand and dust mixed with lubrication will stall the fiber and cause unnecessary friction, which effects the fiber blowing distance negatively. Make sure the duct is clean and dry before sending two or more sponges with the correct lubrication through the duct. Depending on your fiber blowing circumstances, the blowing distance can be improved by 50 % or more just by cleaning the duct and lubricating it.

2. Do not fill duct capacity more than 70%

You must ensure plenty of space between the cable and the inside of the duct, as it makes the fiber blowing go smoother. The right setup will save you time and money.

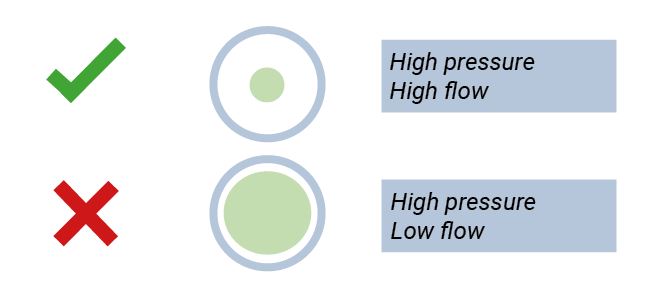

3. Dispense air correctly

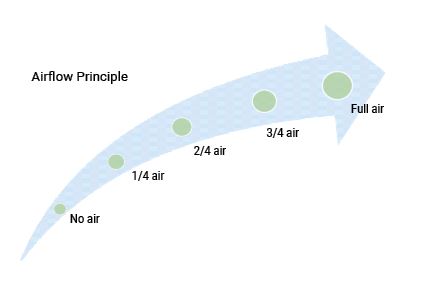

If you use more air than needed, you can risk running out of it before reaching the planned distance. Why blow a shorter distance because of incorrect use of air?

Gradually increase air pressure by 2 bars when cable speed decreases. Wait and observe. You will see a greater project progress.

4. Use the correct compressor. The magic starts when you can keep a pressure of 10 bar

The correct compressor secures the quality and success of your fiber blowing job. The compressor you select must be able to produce more air than you need.

Being able to keep a constant pressure of 10 bar is important when choosing the compressor. If you cannot keep this pressure, it means your compressor cannot produce enough air to reach your distance making it the wrong compressor.

If the air is used faster than the compressor can keep up, the pressure will drop, and you have a compressor that is too small.

So to maximize your fiber blowing job, the correct compressor is vital.

Remember the magic starts when you can keep a pressure of minimum 10 bar.

5. Use the correct size machine for the chosen cable and duct

Using the correct machine, secures the fiber. A small machine may not have sufficient power, and a large machine can have too much power, which can be damaging for the fragile fiber. That is why it is important to use the correct machine for the job in order to use your time and money effectively.

When in doubt, we recommend you to contact Fremco or one of our appointed resellers around the world for a competent feedback in your purchase – maximizing your fiber blowing installation and distance.